Chautauqua Chemicals Co., Inc. manufactures and distributes a wide variety of electroplating and metal finishing supplies including electro cleaners, etching chemicals, acid activators, plating equipment, anodes & anode bags, conversion coatings, commodity chemicals, and plating additives for metal finishing applications.

Specialty Plating Supplies

Electrocleaners

Miraclean IC-290

Miraclean IC-290 is a heavy-duty phosphate-free powdered degreaser for use in soak applications. It is for use only on steel and brass.

Miraclean EC-220

Highly alkaline liquid soak and electrocleaner for ferrous metals, copper, and copper plated work. Has been formulated to be free rinsing, low foaming, and highly conductive (5% solution – 62 mS per cm). Will remove a variety of soils including oils, greases, and lubricants. Can also be used as a spray cleaner. Will also keep plating barrels and other equipment clean and free of oils.

MC 520

Silicate-free heavy-duty detergent for use in soak and ultrasonic cleaning systems. It is safe for use on stainless steel, nickel, cobalt chrome, and titanium alloys. Excellent for removing polishing compounds and blast media from medical implants and instruments. It can also be used to remove general machine oils.

Miraclean EC-179

Dry, highly alkaline, granular product with a high sequestering ability and high surfactants. It is for use on ferrous metals only.

Miraclean EC-140

Highly alkaline liquid soak and electrocleaner for ferrous metals. Has been formulated to be highly conductive, free rinsing, and low foaming. Will also keep plating barrels and other equipment clean and free of oils. Can also be used as a spray cleaner.

Miraclean LB-620

Concentrated liquid caustic product for use as a component of a soak or electrocleaner for steel. Excellent for removal and emulsification of oils and grease from ferrous metals.

Miraclean EC-315

Concentrated liquid product for use with Miraclean LB-620 as an excellent anodic electrocleaner for steel parts. Miraclean EC-315 is excellent for removal of oil and smut.

Miraclean S-170

Miraclean S-170 is a concentrated liquid product for use as a component of a soak cleaner for steel. Excellent for removal of oils and grease from ferrous metals.

Etchants

Miraclean Deoxidizer

A liquid acidic compound designed to remove oxides, stains, and smut from stainless steel, aluminum, copper, brass, zinc, magnesium, titanium, zirconium and iconel.

Miraclean Deoxidizer 500

A liquid acidic compound designed to remove oxides, stains, and smut from stainless steel, aluminum, titanium, zirconium and iconel.

Mirapic ME-811

A water-soluble, dry powder containing acid salts with the addition of nitric acid to process Zamak-3 zinc die castings (Mix 1) and high silicon aluminum (Mix 2). Both treatments result in a leveled and fine-grained activated surface for post-seeding chemical or electroplating operations.

Mirapic ME-815

A water-soluble, dry powder containing acid salts. Mirapic ME-815 is added to sulfuric acid to deoxidize and activate copper and copper alloys. Contains no phosphate, fluorides, chromate, ammonia, nitrate, or chloride. Will restore copper appearance on copper alloys, enhance the appearance of brass alloys that are dezinced at the surface, and be used as a chromate-free deoxidizer on certain aluminum alloys.

Mirapic ME-810

A water-soluble, dry powder containing fluoride-bearing salts, which can be used to replace hazardous hydrofluoric acid. (1 oz. per gal. in water with the addition of sulfuric, nitric, or hydrochloric acid is equivalent to 1% by volume of 60% hydrofluoric acid).

Miraclean SS Etch

A liquid acidic compound designed to etch and condition stainless steel surfaces prior to brazing, rubberizing, or resin coatings. Is stabilized to deliver a uniform and specific etch rate over a long period of time.

Acid Salts

Acid Salt 829

A dry powder containing acid salts and surface active agents. For use with water on all metal as a replacement for mineral acids.

Acid Salt 839

A dry powder containing acid salts and surface active agents. For use with water on all metal as a replacement for mineral acids.

Mirapic AS-839L

A liquid version of Acid Salt 839. It is a blend of acid salts and surfactants. Used for activating steel, copper alloys, and zinc. Unlike conventional mineral acids, dilution with water products produces less heat. Normal precautions when working with mineral acids should be observed.

Activator 34

A dry powder containing acid salts and surface active agents. Activator 34 is for use with water on all metal as a replacement for mineral acids. Activator 34 is very effective on zinc die cast alloys, tin, lead, leaded brass, bismuth alloys, white metals, and beryllium copper.

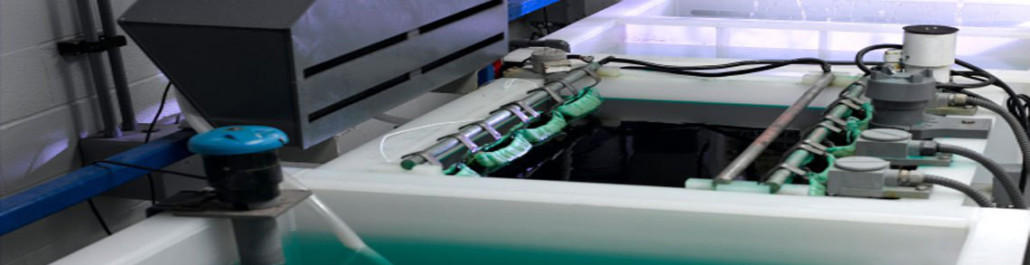

Electroplating Equipment

Auto Control & Testing Equipment

- Salt Spray

- Hull Cells

- Thickness Testers

- Lab Reagents

- Brightener Feeders

- SPC Systems

- Auto Cleaner Controls

- Metering Pumps

Exhaust Systems

- Hoods & Ductwork

- Blowers

- Fans

- Scrubbers

- Completely engineered systems

Filters

- Permanent Disc

- Horizontal Disc

- Tube Chamber

- Carbon Chambers

- Bag Filters

- Filter Media

Heating & Cooling

- Electric Immersion

- Screw Plug

- Teflon Coils

- Steam Coils

- Temperature Controllers

- Level Controllers

- Chillers

Plating Accessories

- Barrels

- Baskets, Racks

- Anodes & Anode Bags

- Anode Baskets

- Spin Dryers

- Power Supplies

- Replacement Parts

Plating Systems

- Manual

- Overhead hoist Automatic

- Sidearm Automatic

- Manual Hoist

Pumps

- Vertical

- Horizontal Centrifugal

- Drum

- Metering

- Air Diaphragm

- Hand Transfer

Pure Water Systems

- Reverse Osmosis

- Softeners

- Deionizers

- Carbon Unit

- Resins

- Flocculating/Chlorinating System

Tank & Tank Liners

- Standard Molded Tanks

- Open Top Tanks

- Custom Fabricated polyvinyl chloride (PVC), polypropylene (PP), steel, and stainless-steel

- Bulk Storage Tanks

- Cone Bottom Tanks

- Containment Basins

- Drum Spill Pallets

- Neutralization Tanks

- Tanks and Mixer Packages

Wastewater Systems

- Neutralization/Precipitation

- Electrowinning

- Ion Exchange

- Atmospheric Evaporation

- Polishing Filters

- Filter Presses

- Sludge Dryers

Anodes

Brass

80/20 and 70/30

- Balls

- Bars

- Nuggets

Cadmium

- Balls

- Bars

Cobalt

- Balls

- Bars

Copper

OFHC (Oxygen Free)

Phosphorous (0.04-0.06%)

- Balls

- Bars

- Nuggets

Insoluble Anodes

- Carbon

- Graphite Steel

- Stainless Steel

- Platinum Titanium

- Platinum Clad Niobium

- Ebonel

Nickel

Electrolytic (“R”)

Sulfur Activated (“S”)

Depolarized

- Rounds

- Crowns

- Pellets (Shots)

- Sheets

- Bars

Silver

- 99.95% Purity Bars

Tin

Cast and Extruded

- Balls

- Bars

- Nuggets

Tin/Lead

Cast and Extruded Alloys

- Balls

- Bars

- Nuggets

Zinc

- Balls

- Bars

- Zinc Dust

Anode Bags

Features

- Anode Bags for Every Basket

- Quick Delivery

- Made to Order on Site

- Emergency Service Available

- Affordable Prices

- Spun or Napped Polypro

- Superior Belt and Suspender Option to Prevent Sagging

- Pre-laundered Option, No Leaching Necessary

- Lunch Box Styles for Reel-To-Reel Platers

Plating Solutions

- Watts (Bright) Nickel

- Nickel Sulfamate

- Woods Nickel

- Semi-Bright Nickel

- Nickel Fluoborate

- Acid (Sulfate) Copper

- Pyrophosphate Copper

- Copper Fluoborate

- Cyanide Copper

- Alkaline Non-Cyanide Copper

- Acid (Sulfate) Tin

- Acid (Fluoborate) Tin

- Tin-Lead MSA (Methane Sulfonic Acid)

- Tin-Lead Fluoborate

Materials Available

- Polypropylene or Napped Polypropylene (instead of double bagging)

- The Temperature May Dictate Modacrylic

- Polypropylene or Napped Polypropylene (instead of double bagging)

- Polypropylene

Conversion Coatings

Boiler/Cooling Tower Chemistry

- Dispersants

- Inhibitors

- Biocydes

- Descalers

Blackening, Oxidizing, Antiquing, Coloring

- Hot Black Oxides for Steel, Stainless Steel, Copper, Brass, Zinc, Nickel, Iron

- Room Temperature Blackening for Steel, Stainless Steel, Copper, Brass, Nickel, Aluminum

- Verdi-Green for Copper and Brass

Conversion Coatings

- Passivation

- Anodizing

- Black Oxide

- Chromate

- Phosphates

Coolants/Lubricants:

- Dry Film

- Synthetics

- Oils and Soluble Oils

- Biocides

- Drawing, Honing, Drilling, Tree-Panning, Broaching, Lathe, Tapping, Forming, Stamping Products

- Vanishing Oils

- Hydraulic & Compressor Oils

- Non-Chlorinated Oils

Electropolish

- Stainless Steel

- Copper

- Brass

Phosphating

- Iron, Zinc, Manganese, and Organic Conversion Coatings

- Spray & Immersion

- Seals-Chrome, Non-Chrome, Oils

- Accelerators-Grain Refiners

- Pre-Cleaners

- Dip/Spin, Dip/Drain Paints

Plastisols

- Air and Heat Cured Primers for Tool Handles

- Plating Racks

- Protective Coatings

Seals/Topcoats

- Emulsion Oils

- Lacquers

- Waxes

- Dry-Film Lubricants

- Water Displacing Oils

Waste Treatment

- Emulsion Breaking

- Coagulants

- Depuratives

- Metal Scavengers

- Polymers (Flocculants)

- Odor Controls

Commodity Chemicals

A’s

- Acetic Acid Glacial

- Acetone

- Activated Carbon (Granular & Powdered)

- Aluminum Sulfate

- Ammonia Anhydrous Gas

- Ammonium Bifluoride

- Ammonium Chloride

- Ammonium Hydroxide

- Ammonium Oxalate

- Ammonium Persulfate

- Ammonium Sulfamate

- Ammonium Sulfate

- Ammonium Thiosulfate

- Aqua Ammonia

B’s

- Barium Carbonate

- Bicarbonate of Soda

- Borax

- Boric Acid

- Brominating Pool Tablets

- Butyl Acetate

C’s

- Cadmium Oxide

- Calcium Carbonate

- Calcium Chloride

- Calcium Hypochlorite

- Calcium Polysulfide Liquid

- Caustic Potash

- Caustic Soda Bead (Sodium Hydroxide)

- Caustic Soda Flake

- Caustic Soda Liquid (Technical Grade)

- Caustic Soda Liquid (Membrane Grade)

- Cellulose (Various Grades)

- Chlorine Gas

- Chromic Acid

- Citric Acid

- Cobalt Chloride

- Cobalt Sulfamate

- Cobalt Sulfate

- Copper Carbonate

- Copper Chloride

- Copper Cyanide

- Copper Fluoborate

- Copper Sulfate

D’s

- Denatured Alcohol

- Diacetone Alcohol

- Diatomaceous Earth (Various Grades)

- Diethylene Glycol

- Dipotassium Phosphate

- Drummond Soap

E’s

- Ethanol 3-190

- Ethyl Acetate 99%

- Ethylene Glycol

F’s

- Ferric Ammonium Oxalate 25%

- Ferric Chloride

- Ferric Sulfate

- Ferric Manganese

- Ferrous Sulfate

- Fluoboric Acid

- Formic Acid 90%

G’s

- Gluconate 60 Liquid GA-7

- Glycerine

- Glycol Ether DB

- Glycol Ether DPM

- Glycol Ether EB

- Glycol Ether EE Acetate

- Glycol Ether EP

- Glycol Ether PM

H’s

- Hydrazine Solution 35%, 54.4%

- Hydrobromic Acid 48%

- Hydrochloric Acid

- Hydrochloric Acid 70%

- Hydrofluosilicic Acid (HFS)

- Hydrogen Peroxide 35%

- Hydroquinone

- Hydroxyacetic Acid 70%

I’s

- Isopropyl Acetate

- Isopropyl Alcohol

L’s

- Lead Fluoborate

- Lead Methane Sulfonic Acid

- Lime, Hydrate

- Limestone, Pulverized

M’s

- Magnesium Chloride

- Magnesium Hydroxide

- Magnesium Oxide

- Magnesium Sulfate

- Malic Acid DL

- Metasilicate

- Methane Sulfonic Acid

- Methanol

- Methyl Amyl Ketone (MAK)

- Methyl Ethyl Ketone (MEK)

- Methyl Isobutyl Ketone

- Methylene Isobutyl Ketone

- Methylene Chloride

- Mineral Spirits (Includes Odorless)

- Monosodium Phosphate

- Muriatic Acid (Hydrochloric)

N’s

- N-Butanol

- Nickel Bromide 18%

- Nickel Carbonate

- Nickel Chloride

- Nickel Fluoborate

- Nickel Sulfamate 24 oz.

- Nickel Sulfate

- Nitric Acid

- N-Methyl Pyrrolidone

- N-Propanol #1

O’s

- Oxalic Acid

P’s

- Perchloroethylene

- Perchloric Acid

- Phosphoric Acid

- PM Acetate

- Polyethylene Glycol 1000

- Potassium Bicarbonate

- Potassium Carbonate

- Potassium Chloride

- Potassium Citrate

- Potassium Copper Cyanide

- Potassium Dichromate

- Potassium Gold Cyanide

- Potassium Hydroxide

- Potassium Nitrate

- Potassium Permanganate

- Potassium Stannate

- Proprietary Solvent

- Propylene Glycol

R’s

- Rochelle Salts

S’s

- Salt (Various Grades)

- Sequestrone EDTA 220

- Silicate of Soda Grade 40, 42

- Silver Cyanide

- Sodium Acetate

- Sodium Aluminate

- Sodium Bifluoride

- Sodium Bisulfite 38%

- Sodium Carbonate (Light & Dense)

- Sodium Chlorate

- Sodium Citrate

- Sodium Copper Cyanide

- Sodium Cyanide

- Sodium Dihromate

- Sodium Fluoride

- Sodium Gluconate

- Sodium Hexametaphosphate

- Sodium Hydrosulfite

- Sodium Hydroxide (see Caustic Soda)

- Sodium Hyporchlorite

- Sodium Hypophosphite

- Sodium Metabisulfite

- Sodium Nitrate

- Sodium Persulfate

- Sodium Silicofluoride

- Sodium Stannate

- Sodium Sulfide

- Sodium Thiosulfate Anhydrous

- Sodium Tripolyphosphate

- Stannous Chloride

- Stannous Fluoborate

- Stannous Sulfate

- Sulfamic Acid

- Sulframin 40 DA

- Sulfur Dioxide, Gas

- Sulfur Solid-Ground Powder

- Sulfuric Acid

T’s

- Tetrasodium Pyrophosphate

- Tin Methane Sulfonic Acid

- Toluene

- Tripotassium Phosphate

- Trisodium Phosphate

- Trycol 5944-A-Surfactant

V’s

- VM&P Naptha

X’s

- Xylene

Z’s

- Zinc Chloride

- Zinc Cyanide

- Zinc Oxide

- Zinc Stearate

Plating Additives

Black Chrome

- Black Chrome

Brass

- Cyanide

Bronze

Cadmium

- Acid

- Cyanide

Chrome (Decorative)

- Hexavalent

- Trivalent

Copper

- Cyanide

- Alkaline Non-Cyanide

- Acid (Sulfate)

- Electroless

- Pyrophosphate

Electroless Nickel

- Low Phosphorous

- Mid Phosphorous

- High Phosphorous

- Nickel-Boron

- Bright

- Semi-Bright

- Recoverable

- Low Stress

- High Build

Gold

- Electronic

- Decorative

Hard Chrome

- Catalyzed

- Including Fluoride-Free

Mechanical Plating

- Zinc

- Tin

- Chromium

- Zinc/Tin

- Zinc/Aluminum

- Brass

- Copper

Nickel

- Watts (Bright)

- Semi-Bright

- Velours

- Black-Nickel

- Micro-Porous

Nickel Sulfamate

Nickel Alloys

- Nickel/Iron

- Nickel/Cobalt

Paladium

Silver

Tin Alloys

- Tin/Lead

- Tin/Cobalt

Tin

- Acid

- Alkaline

Zinc

- Acid (Including Mixed Salts)

- Alkaline Non-Cyanide

- Cyanide

Zinc Alloys

- Zinc/Cobalt

- Zinc/Iron

- Zinc/Nickel